Q8Oils has recently signed a commercial and marketing agreement with the company XEV in Italy, that produces 3D printed electric vehicles. This agreement shows Q8Oils’ continuous efforts to remain one of the lubricants most innovative companies.

Innovation has always been in the heart of Q8Oils’ activities. In everything we do, we aim to find innovative solutions for common challenges. Therefore, we are happy to announce that we have recently signed a commercial and marketing agreement with the company XEV in Italy. XEV is an innovative start-up that produces revolutionary 3D printed electrical cars, combining additive manufacturing and intelligent urban mobility.

About XEV

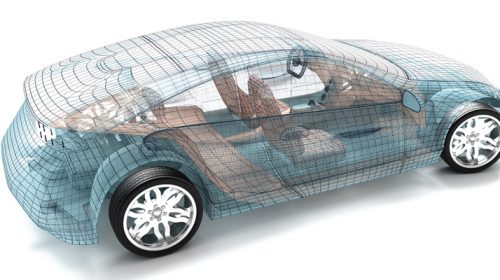

XEV has developed industrial 3D printing technologies and processes for automotive mass production. They use 3D printing to give customers an ultimate user experience through fast product development, customization and flexibility of design. 3D printing eliminates the need for model specific tooling and allows virtually limitless personalization. This new tooling-less manufacturing process reduces cost and development time by up to 90 percent.

XEV urban electric vehicles combine a flexible modular chassis, beautifully designed 3D printed interior and exterior panels together with a comfortable, easy to use driving experience. The style of the vehicle can be updated and changed easily for a cost of an iPhone upgrade.

The goal of XEV is to capitalize on the benefits of Industry 4.0 in order to reach Zero manufacturing waste, Zero cost of customization, maximize the use of Smart Data and provide ultimate customer experience.

The benefits of 3D printing technology in automotive

Traditional car production methods typically involve large, complicated molds and tools that are not only expensive, but also part-specific. The 3D printing production line of XEV virtually eliminates the need for such limited and resource intensive tooling, resulting in a flexible and efficient manufacturing process.Thanks to a pre-designed standarized chassis, the 3D pieces can be modified and changed with significantly less re-engineering.

In general the 3D printing technology allows for fewer components, faster technical updates and significantly reduced production cycles. It also dramatically reduces production costs meaning the savings can be passed on to the end customers.

Why collaborate?

With this new collaboration, Q8Oils and XEV will be able to take advantage in both commercial and marketing activities. In all XEV electric cars registered in Italy, XEV will recommend to use Q8Oils lubricants in the maintenance booklet.

The mission of XEV is to reduce waste of materials, time and money created by traditional manufacturing. That is what makes them the perfect partner for Q8Oils’ sustainability mission. This agreement shows Q8Oils’ continuous efforts to remain one of the most innovative lubricants companies.