The number of high efficiency engines on the market is increasing every year. These innovative systems are setting challenging requirements for oil manufacturers. Especially gas engines are subjected to extreme operating conditions and call for advanced lubricants with an outstanding oxidation stability and a low ash deposit tendency. The Q8 Mahler has proved to fit the bill for many gas engine owners.

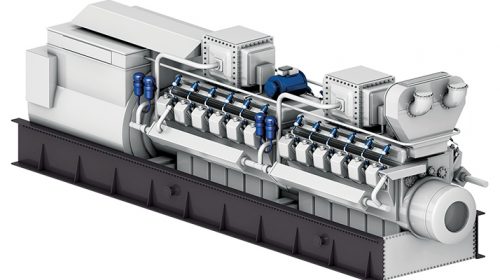

Designed for extreme conditions

Designed for extreme conditions

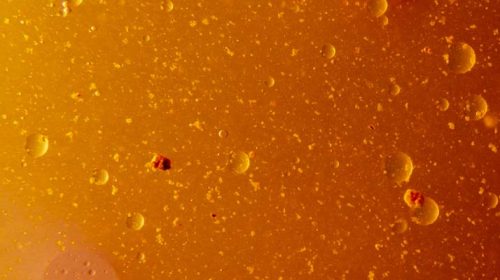

Modern gas engines work in extreme conditions, speeding up the deposit formation process in the oil and thus increasing the risk of ring sticking and valve seat recession. The Q8 Mahler range is exactly designed to perform in these severe circumstances. These high quality oils can be used for all gas types, including natural gas. The innovative ‘keep clean’ technology offers a range of benefits:

- Extended oil drain intervals due to high oxidation resistance

- Low ash deposit tendency and good resistance against pre-ignition

- Good acid neutralizing capacities as a result of high

- TBN retention

- Excellent anti-wear properties, protecting against valve seat recession, ring sticking, rust and corrosion

Extended oil drain interval

Many customers have experienced the benefits of extended oil drain intervals and the low deposit tendency of the Q8 Mahler range.

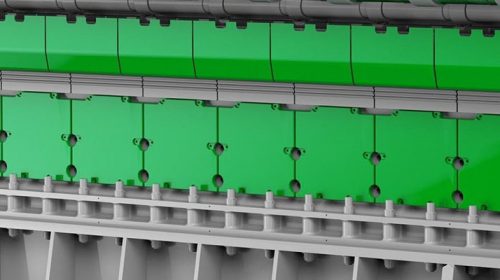

A Dutch company that produces green electricity from biogas replaced the oil in his two Jenbacher JMS 316 stationary gas engines with the Q8 Mahler G10 SAE 40. This high ash, stationery gas engine oil is developed for use with bio- and landfill gasses. It has been developed as a high TBN product with a low deposit tendency. The company owner was delighted to see the oil drain interval of his engines increased with 54 %. He declared: “Very happy with the results, with very little deposit build up on the piston crowns and cylinder heads.”

‘Keep clean’ technology

Another customer uses a INNIO Jenbacher 612, F version with steel piston to power the lamps in his greenhouses. The heat is used to warm up these premises. We tested the performance of the Q8 Mahler G5. The results after 6.000 hours proved its excellent technology. The ring grooves were still extremely clean and there was no sign of deposits or ring sticking. Once again a confirmation of the excellent ‘keep clean’ technology of Q8 Mahler G5.