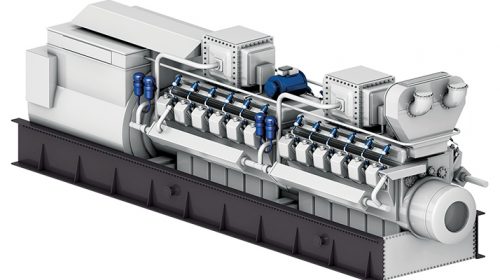

While the refrigerant is essential for the cooling properties of a refrigeration system, the refrigeration machine oil is crucial for the proper functioning of the compressor. Lubricants for refrigeration compressors reduce friction, prevent wear and seal between the high and low pressure sides. But how do you choose the right refrigeration machine oil?

Although the main function of refrigeration oil is still lubrication, it should also withstand extreme temperature differences and be compatible with the refrigerant.

Wie funktioniert ein Kühlsystem?

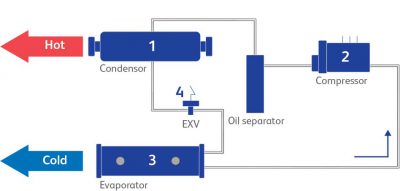

The most common refrigeration cycle is achieved by circulating, evaporating and compressing the refrigerant in a closed system. Evaporation occurs at low temperature and pressure, while condensation occurs at high temperature and pressure. This makes it possible to transfer heat from a low temperature area to a high temperature area. Figure 1 gives an overview of this refrigeration cycle.

- Hot compressed vapor enters the condenser where it is cooled and condensed into a liquid, producing heat.

- The refrigerant enters the compressor in the vapor phase and is compressed to a higher pressure, which increases the temperature.

- The cold mixture enters the evaporator. The liquid part of the cold refrigerant mixture is evaporated.

- The condensed liquid refrigerant flows through an expansion valve where the pressure is reduced. The pressure drop causes part of the liquid refrigerant to evaporate. This causes the temperature of the liquid and vapor refrigerant mixture to drop.

Welche Kältemittel werden für Kühlsysteme verwendet?

- CFCs (chlorofluorocarbon): These refrigerants are the most harmful to the ozone layer. Examples: R11, R12, R13, R13b1, R14, R113, R114 and R115.

- HCFC (hydrofluorocarbon): These refrigerants are slightly harmful to the ozone layer. Examples: R21, R22 and R123.

- HFC (hydrofluorocarbon): These refrigerants are not harmful to the ozone layer. Mineral oil, PAO or alkyl benzenes are not compatible with HFCs. Examples: R134a (used in car air conditioning systems) and R152a.

- Ammonia (R717 (NH3): Although ammonia is environmentally friendly, pure ammonia gas is highly toxic to humans. Ammonia is often used in large industrial refrigeration systems.

- Mixtures of CFC, HCFC and HFC refrigerants are also available on the market. Examples of such mixtures are: R500 (=R12/R152a), R501 (=R22/R12) and R502 (R22/R115).

Wie wählt man das geeignete Kältemittel aus?

The most important properties of refrigerants are:

- boiling point

- Heat needed to evaporate the liquid

- Density in the liquid and vapor phases

The selection of the right refrigerant is essentially based on the suitability of its pressure-temperature ratio for the respective area of application. The temperatures of the refrigerant in the evaporator and condenser correspond to the temperatures of the cold and warm sections. This determines the operating pressures in the evaporator and condenser.

Anforderungen an Kältemaschinenöle

1. Thermal stability

Refrigeration machine oils must function properly over a wide temperature range. End of compression temperatures in refrigeration compressors can reach peak temperatures of up to 180ºC. Therefore, the refrigeration machine oil must be heat-resistant. If the oil contains volatile oil fractions, the lighter ends enter the compressor system as vapor where they condense, reducing heat transfer efficiency but also increasing oil viscosity.

2. Chemical stability

Refrigeration machine oils should be chemically stable to avoid reaction with the refrigerant.

3. Solubility of the refrigerant/oil

Refrigerant/oil mixtures can be (partially) soluble or insoluble. Complete solubility facilitates lubrication, but can result in significant drops in viscosity in the compressor, increasing friction and wear. Table 1 provides an overview of the various refrigerants available on the market and their solubility properties in combination with mineral oil (Q8 Stravinsky N).

| Completely soluble | Height

solubility |

Average solubility | minor

solubility |

Not

soluble |

| R11

R12 R21 R113 R500 |

R13b1

R501 |

R22

R114

|

R13

R14 R115 R152a R502 |

NH 3

CO2 _ |

Table 1: Solubility of refrigerants in mineral oil (Q8 Stravinsky N)

To function properly, the oil/refrigerant mixture should have a viscosity high enough to ensure adequate sealing and lubrication in the compressor.

How do you read a viscosity-temperature graph?

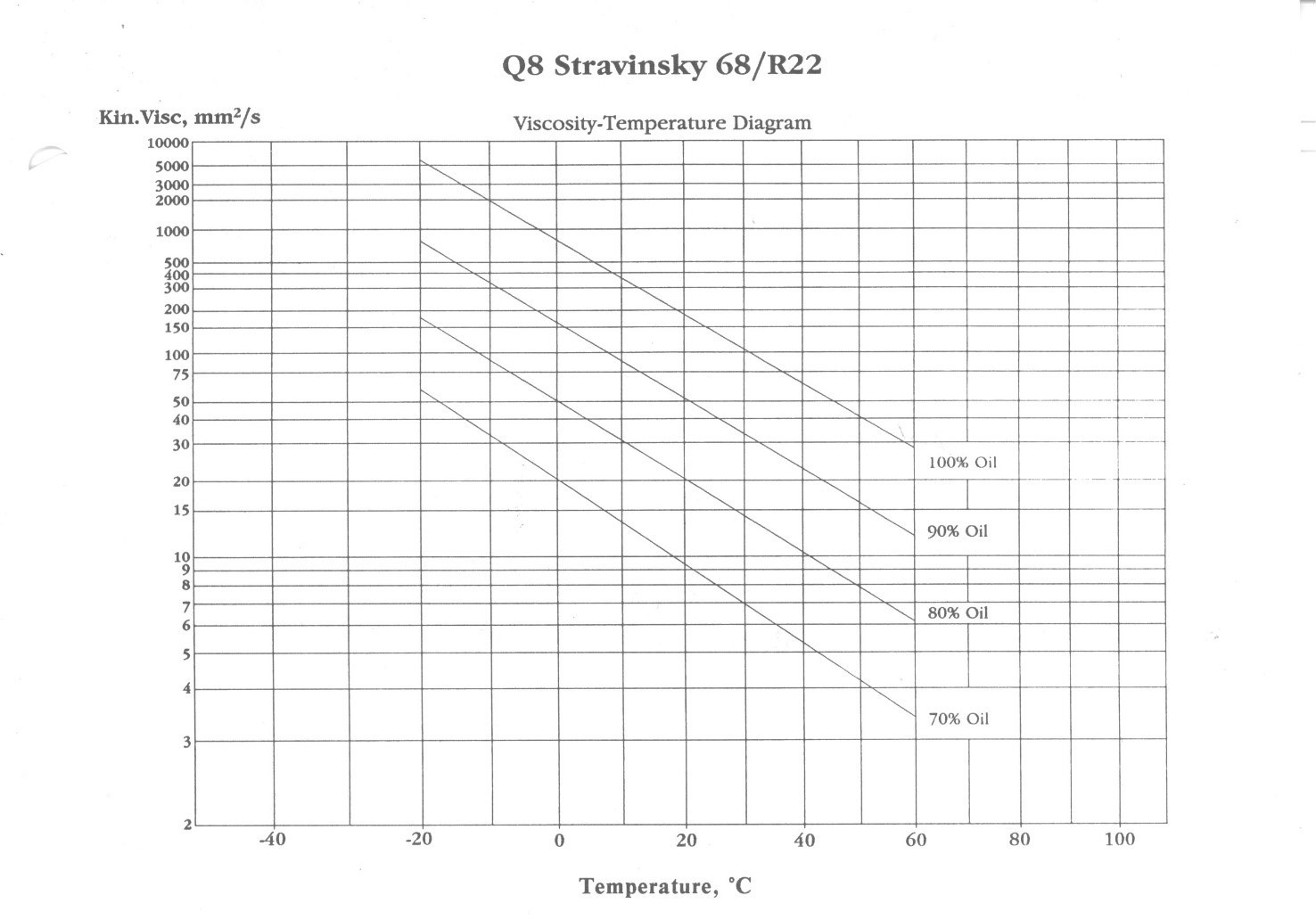

Figure 2 shows the viscosity-temperature diagram of various blends of Q8 Stravinsky 68 and R22. The figure shows that the viscosity can decrease significantly even when the refrigerant content in the mixture is low. Too low a viscosity leads to increased friction and wear. Anti-wear additives are generally not used in refrigeration machine oils because of the risk of a reaction between the additives and the refrigerant.

How do you read a solubility diagram?

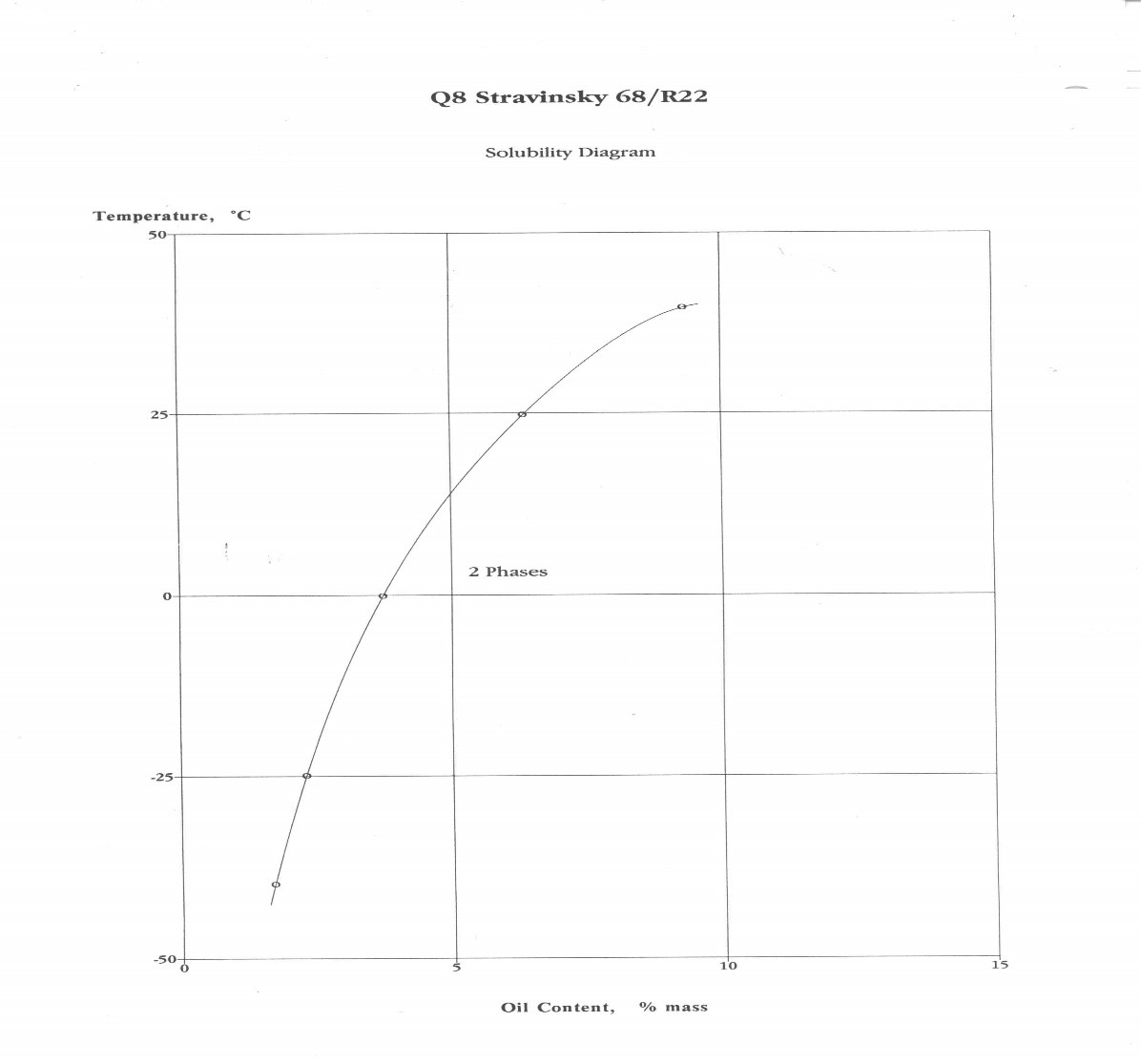

Die Löslichkeit von Q8 Strawinsky 68 und R22 ist abhängig von der Temperatur und der Ölkonzentration. Das bedeutet, dass sich Q8 Strawinsky 68 und R22 nicht über den gesamten Druck- und Temperaturbereich hinweg vermischen. Wenn ein vollständig gelöstes Kältemittel-/Ölgemisch abgekühlt wird, wird ein Punkt erreicht, an dem sich das vollständig gelöste Gemisch in zwei flüssige Phasen trennt. Dies ist im Löslichkeits-Diagramm dargestellt (Abbildung 3). Bei Temperaturen über einem bestimmten Punkt auf der Linie sind die beiden Substanzen löslich, unterhalb der Linie erfolgt eine Trennung.

4. Dampfdruck

Wenn eine Flüssigkeit kocht, wird die zugeführte Wärme genutzt, um die kinetische Energie der Moleküle zu erhöhen, bis sie nicht mehr in der flüssigen Phase verbleiben und zu Dampf (oder Gas) werden können. Dies geschieht bei einem bestimmten Druck. Wird der Druck jedoch erhöht, steigt auch die Siedetemperatur.

Das Verhältnis zwischen Druck und Siedetemperatur unter gesättigten Bedingungen (Flüssigkeit und Dampf) wird als Dampfdruckdiagramm definiert.

Wie liest man eine Dampfdruckkurve?

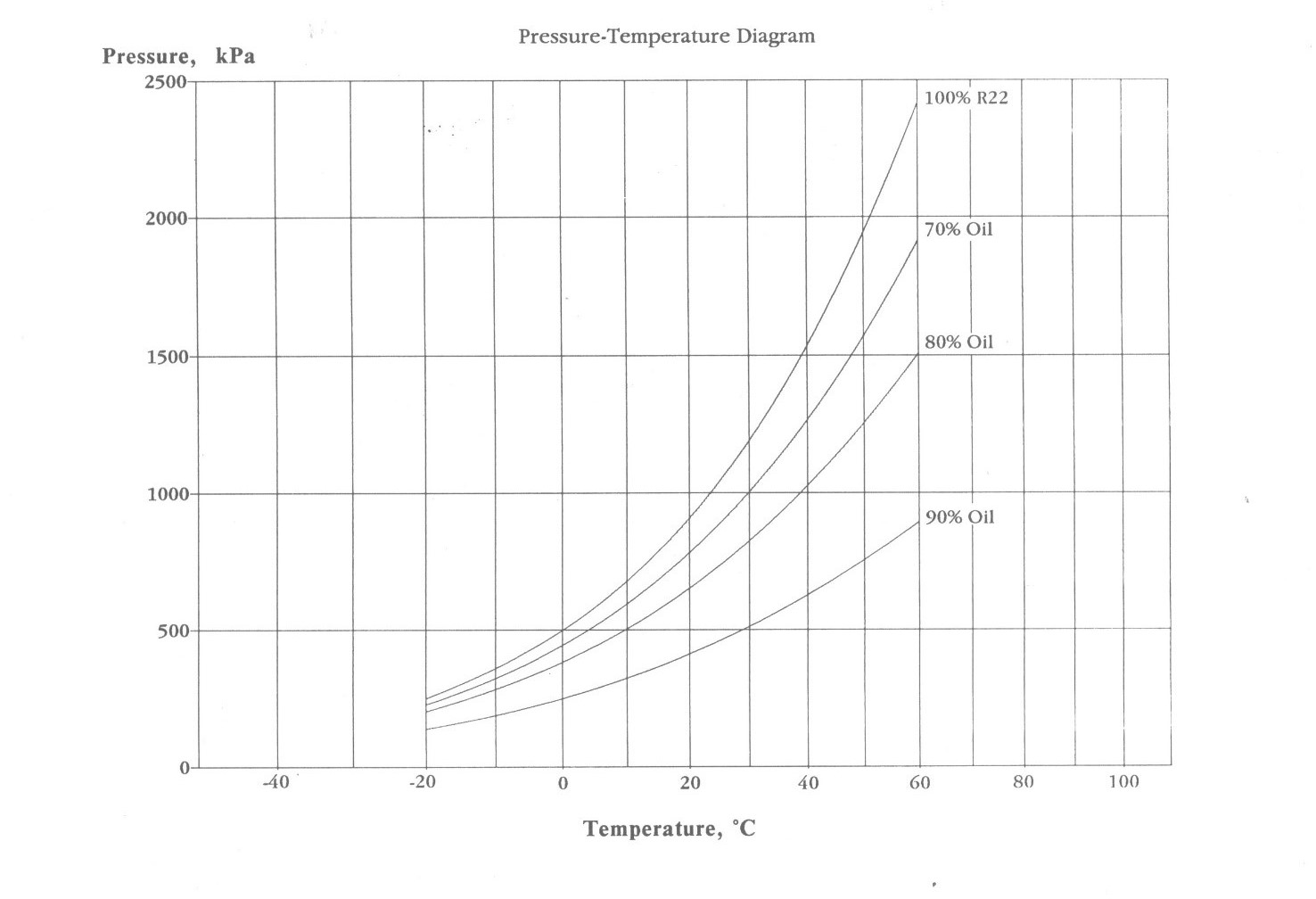

In Abbildung 4 ist das Druck-Temperatur-Diagramm für verschiedene gesättigte Mischungen von Q8 Strawinsky 68 und R22 dargestellt. Die flüssige Phase befindet sich links von der Kurve, die Dampfphase (Gas) rechts von der Kurve. Die Flüssigkeit kann entweder durch Erhöhen der Temperatur oder durch Absenken des Drucks verdampft werden. Dampfdruckkurven sind wichtig, da diese Kurven zum Teil die Bedingungen des vorgesehenen Kühlsystems definieren.

The above vapor pressure curves allow you to determine what the pressure will be for an evaporation or condensation process, which is the basic principle of the vapor compression cycle. When a liquid boils, it removes heat from its surroundings. If the resulting steam is transported to a new location and compressed to a higher pressure, it can be condensed at a correspondingly higher temperature and its heat of condensation is given off to the new environment.

What types of oil are used for cooling systems?

- Alkylbenzenes (AB) : These refrigeration machine oils have good thermal and chemical stability. The miscibility with refrigerants is high. Alkylbenzenes are completely soluble with mineral oils and PAO, which allows the preparation of mixtures to improve lubricating properties.

- Polyalphaolefin (PAO) : These refrigeration machine oils have good chemical and thermal stability. PAO also has excellent viscosity temperature properties. Miscibility with refrigerants is low, which is why PAO in refrigeration technology is mainly used in applications where miscibility is not important. PAO can cause seals to shrink, which can be solved by mixing PAO with AB.

- Polyol Ester (POE) : This refrigeration oil is the most common type of synthetic lubricant used with HFC refrigerants such as R134a.

- Polyalkylene glycols (PAG) : These refrigeration machine oils have a high viscosity index and high thermal stability. However, PAG is hygroscopic, i.e. H. it can attract water. PAG is soluble in ammonia.

- Mineral Oil : Naphthenic oils have a low boiling point making them more suitable at lower temperatures.

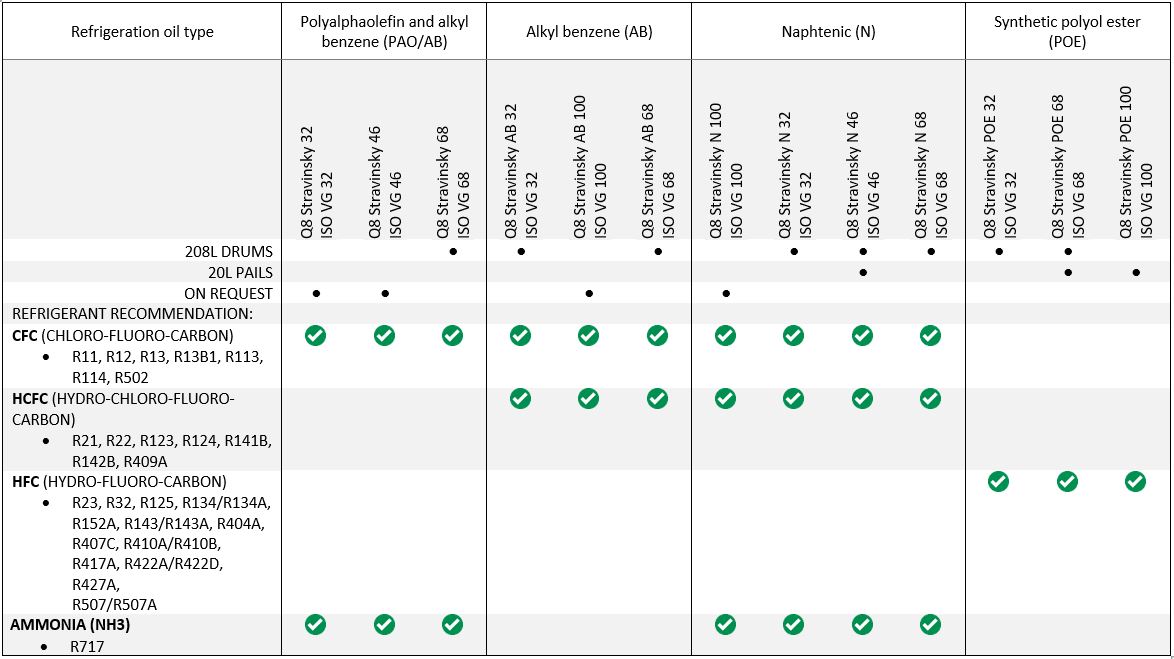

The Q8Oils refrigeration machine oil range

Q8Oils has a complete product portfolio. The range is based on naphthene, alkylbenzenes, mixtures of PAO and alkylbenzenes as well as synthetic polyol esters

Conclusion: Choose your refrigeration machine oil carefully

Choosing the right refrigeration machine oil depends on the specifications of the compressor and the refrigerant used.

The refrigeration machine oil should be chemically and thermally stable and not react with the refrigerant . Also very important is how the refrigeration machine oil interacts with the refrigerant (e.g. solubility properties) and how the mixture reacts in the compressor. Lubricant-related problems can occur in a refrigeration compressor when the lubricant viscosity becomes too low or when oil is not present.