Reduce your machining costs with metalworking fluid management – Part 2 of 2

Reduce your machining costs with metalworking fluid management – Part 2 of 2

Reduce your machining costs with metalworking fluid management – Part 2 of 2

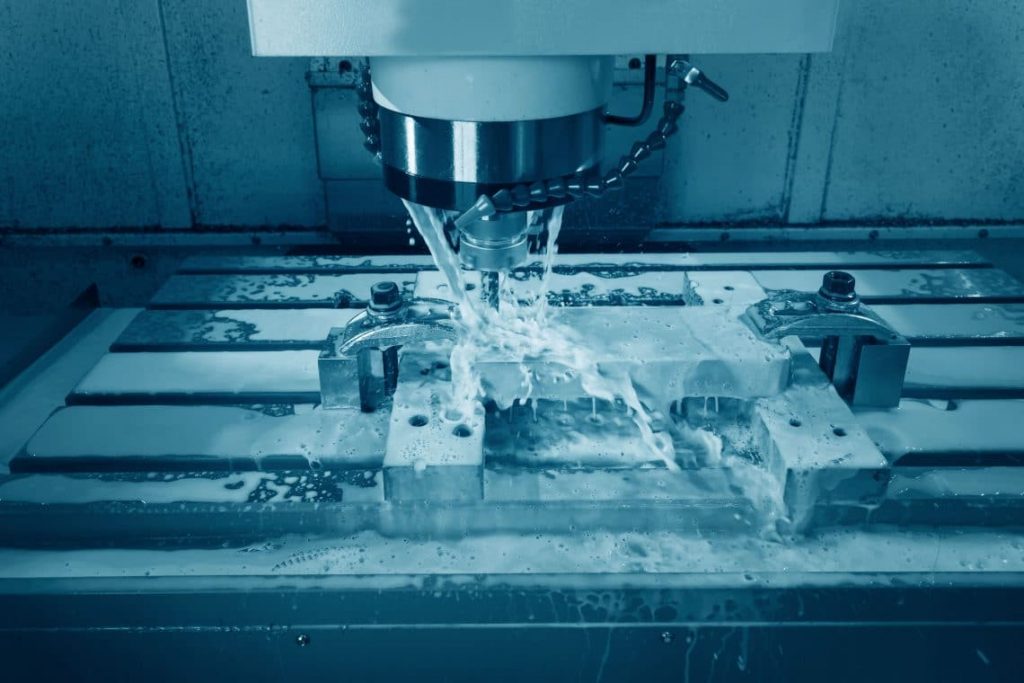

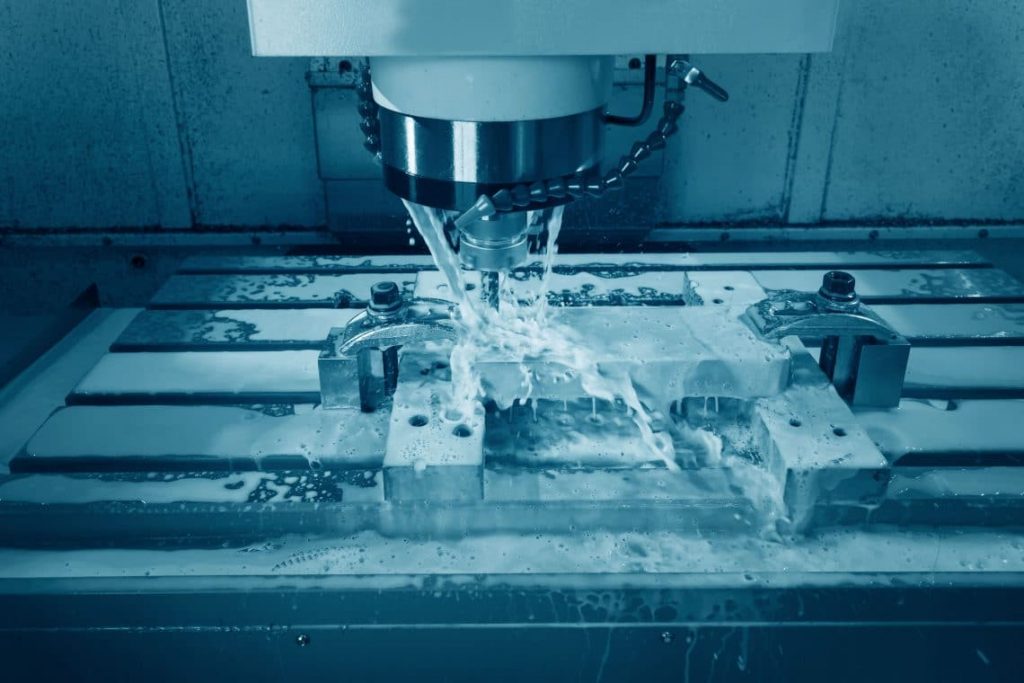

Although often overlooked, metalworking fluid management is an important factor in the manufacturing process. Poor or even lack of MWF management will highly decrease the quality and life of a MWF and produce extended problems in the production process, such as decrease the life time of tools, machines, etc. This means that MWF costs and other manufacturing costs associated with or influenced by MWFs will be high.

Based in Hertfordshire, UK, Pope & Meads is a long-established precision engineering company providing solutions for scientific, defence and aerospace sectors. Services include ultra-high precision machining; general machining; electro-mechanical assembly; cleanroom assembly; parts and material sourcing; specialist finishes/treatments; testing and verification; inspection and reporting; and product cleaning.

The Biocidal Products Committee (BPC) prepares the opinions of the European Chemical Agency (ECHA) related to several processes under the Biocidal Products Regulation. Substances, which were on the market before 14 May 2000 are referred to as existing active substances.

Once our lubricants leave the care of Q8Oils or its agents, their continuing fitness for use depends on the quality of storage and handling procedures. To guarantee a maximal shelf life of your lubricants, you should take into account several guidelines.

At Q8Oils we develop high-performance stationary gas engine oils for many different engine brands. Our unique QRAS-analysis helps us to select the right lubricant for any application and to monitor all key performances of our lubricants. The historical data of these analysis confirm that Q8 Mahler performs extremely well in Liebherr gas engines.

The Q8Oils laboratories are equipped with an extensive range of analytical tools to determine performance and characteristics of newly formulated oils. Among these are high pressure differential scanning calorimeters (HPDSC), kinematic viscosity analysers (KV), rotating pressure vessel oxidation test (RPVOT), total acid number (TAN) and total base number (TBN) analysers, Gas chromatography–mass spectrometry (GC-MS), and Infrared spectroscopy (IR).

Q8Oils has renewed its Q8 Ravel range of corrosion protection fluids.

So how does Q8Oils focus its research and development to achieve:

Cleaner engines

Longer oil drain periods

Lower total operational costs (TOC)

Caterpillar Energy Solutions approved Q8 Mahler GR8 as gas engine oil for the use in MWM TCG and Caterpillar CG gas engines with increased pollutant concentration.