Once our lubricants leave the care of Q8Oils or its agents, their continuing fitness for use depends on the quality of storage and handling procedures. To guarantee a maximal shelf life of your lubricants, you should take into account several guidelines.

The quality of Q8Oils lubricants leaving the blending plant is closely monitored and controlled. Stringent care is taken in manufacturing, packaging and transportation to ensure that the products are free from contaminants, and fully meet or exceed their stated specifications.

However, when lubricants are stored in customers’ warehouses the shelf life of these products depends heavily on the environmental and storage conditions.

Conditions that impact shelf life

Oxidation occurs in all oils that are in contact with air, including stored lubricants. The formulation of the lubricant affects the rate of oxidation and storage life:

- Base oil: Highly refined mineral oils and synthetic hydrocarbons increase shelf life while lower-grade mineral oils and inorganic esters reduce shelf life.

- Additives: The presence of anti-rust and anti-oxidants increases shelf life, while EP-additives decrease shelf life

- Thickener: The presence of the thickener in grease can increase the degradation rate, limiting shelf life.

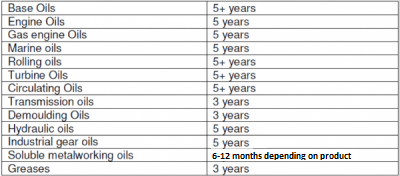

Oil companies generally provide shelf lives for the products they market. Based on a survey of our competitors and our own experience we recommend the following shelf life’s when the product is stored in a closed environment:

However, the rate at which the lubricant degrades, is also impacted by the environmental and storage conditions.

The most important factors that impact lubricant shelf life are:

- Storage temperature: increasing the temperature at which the lubricant is stored by 10°C (by 18°F) doubles the oxidation rate, which cuts the usable life of the oil in half.

- Exposure to light

- Humidity, oxygen: the presence of water increases the rate of oxidation.

- Storage environment (covered or open, indoor or outdoor)

How to store lubricants indoor

All lubricants are best stored indoor where temperature variations are limited. If indoor space is limited, you should give priority to small packages, opened packages and lubricants which can be affected by frost. Rarely will indoor temperatures fall so low that they will affect a lubricant adversely.

On the other hand, it is recommended to avoid excessive local heat from steam pipes, furnaces, heaters, etc. to prevent thermal degradation or volatilisation of solvent containing grades. The warmest part of a warehouse or store should be reserved for high viscosity oils to make dispensing easier. Stored lubricants should be kept dry at all times to prevent the corrosion of containers.

How to store lubricants outdoor

Outdoor storage of lubricants is possible if the products are protected from extreme temperatures and water ingression. Most lubricants are unaffected by other climatic conditions and can be stored outdoor for limited periods of time. However, if temperatures below 0°C (32°F) are anticipated, protection should be given to lubricants which are sensitive to the effects of frost such as oil/water emulsions and water soluble fluids.

The following products should never be stored outdoor:

- Insulating Oils

- Refrigerator Oils

- Greases

- Neat Cutting Oils containing fatty oils or compounds, which can solidify and separate when very cold.

Oil barrels standing in the open suffer temperature- and internal pressure variations. This leads to “breathing” where there is a leaking seal, with moisture liable to be drawn in – particularly if the barrel is standing cap-up, for the top of the barrel forms a rain trap. Water on top of the barrel can also cause rusting.

Smaller packages of lubricants such as drums or pails, are not designed to withstand severe weather conditions. If outdoor storage is unavoidable, you should protect them from rain and humidity while ensuring the free circulation of air.

What to do when shelf life is expired?

If the shelf life of a lubricant is exceeded, it does not mean that the product is no longer useable. In such cases a sample could be sent to Kuwait Petroleum Research & Technology centre (KPR&T) to evaluate possible product deterioration. After analysis of the sample, KPR&T will advise on further use of the product.