Caterpillar Energy Solutions approved Q8 Mahler GR8 as gas engine oil for the use in MWM TCG and Caterpillar CG gas engines with increased pollutant concentration.

New OEM approval for Q8 Mahler GR8 gas engine oils

Caterpillar Energy Solutions approved Q8 Mahler GR8 as gas engine oil for the use in MWM TCG and Caterpillar CG gas engines with increased pollutant concentration.

TEDOM approved Q8 Mahler GR as gas engine oil for the use in natural gas- and biogas engines. The approval was the outcome of two field tests in Italy, showing excellent results on oil stability.

Q8Oils has succeeded to eliminate the undesired side effects of gas engine oils with a high sulphated ash content. The Q8 Mahler G8 gas engine oil combines a 0,8 % sulphated ash content with a low deposit tendency, keeping engine parts clean.

Q8Oils’ performance evaluation test is the answer. It gives our customers a perfect comparative view on oil consumption, engine downtime, production efficiency and the overall value for installation owners.

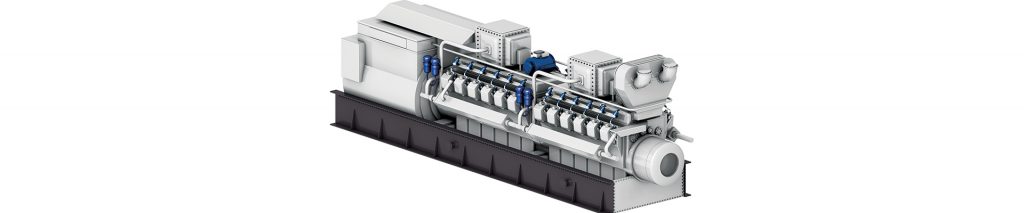

There is an increasing number of high efficiency engines on the market. Gas engines in particular are used in a wide variety of applications such as CHP (Combined Heat and Power), in greenhouses or PowerGen applications to meet fluctuations in local electricity demand. Gas engine systems make use of a broad range of gaseous fuels as fuel gas.

The number of high efficiency engines on the market is increasing every year. These innovative systems are setting challenging requirements for oil manufacturers. Especially gas engines are subjected to extreme operating conditions and call for advanced lubricants with an outstanding oxidation stability and a low ash deposit tendency. The Q8 Mahler has proved to fit the bill for many gas engine owners.

Engine applications with landfill gasses are the biggest challenge for every oil manufacturer. The specific conditions of these engines push the desired quality and performance of oils to the limits.

The energy sector is very demanding when it comes to the performance of lubricants for stationery gas engines. Thanks to its wide-ranging experience in this challenging sector and its innovative R&D program, Q8Oils produces the best-in-class gas engine oils with the best performance and longest drain intervals on the market.

The expansion of Q8Oils’ innovative range of stationary Gas Engine Oils is continuing with the introduction of Q8 Mahler G5 SAE 40. The success of the in-house developed formulations & technology of the Q8 Mahler range has been successfully proven across a variety of engines for over the past 20 years. Globally, there already are an estimated 3,750 engines filled with Q8 Mahler and running for 15 million hours, every year.

Q8 Mahler GR5 is a high-performance stationary gas engine oil, specially developed for operation under mild to severe conditions and blended using a premium, hydrocracked (synthetic) base oil.