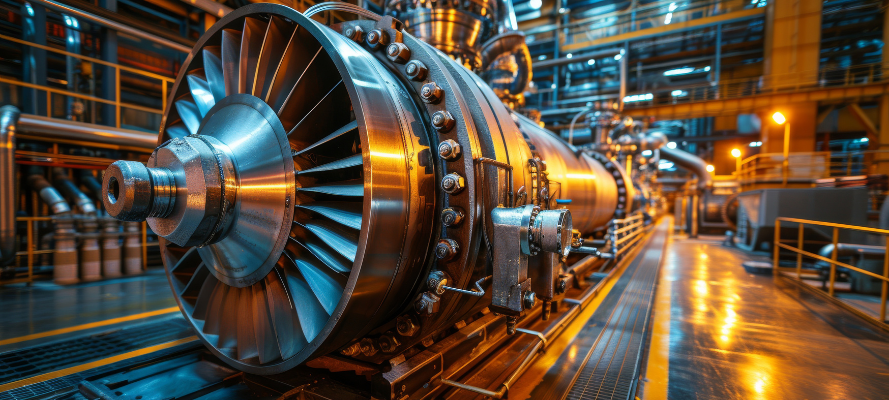

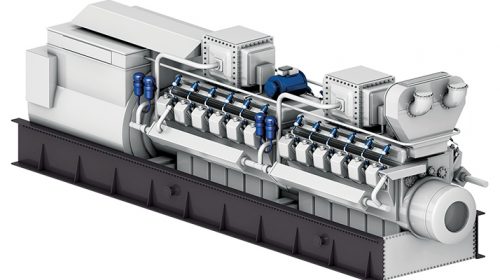

In the world of energy production, turbines do the heavy lifting—powering over 80% of the world’s electricity needs. Whether steam, gas, or hydro-powered, these systems operate under extreme conditions where only the most reliable lubricants will do. That’s where Q8Oils steps in, with high-performance turbine oils designed to extend equipment life, minimise downtime, and reduce the total cost of ownership.

What are Turbine Oils, and why do they matter?

Turbine oils are critical for the smooth operation of turbines, their associated equipment or any R&O (Rust and Oxidation inhibited oil) lubricant systems.

The main purpose of the turbine oils is to provide proper lubrication and cooling of the equipment, while keeping surfaces clean from corrosion, varnish and deposits.

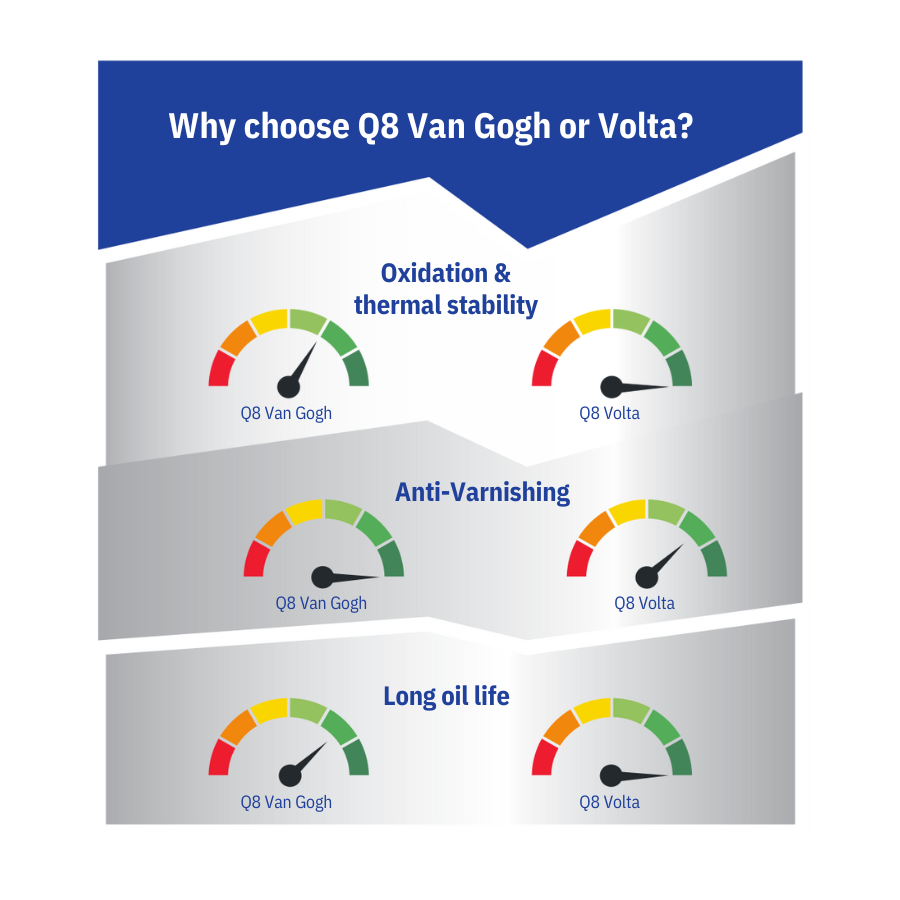

Q8Oils offers two standout solutions for turbine lubrication: Q8 Van Gogh and Q8 Volta. Both products are the result of Q8Oils’ extensive research and in-house development of application specific additive packages. They share a common goal: long oil life, outstanding thermal stability, and reliable protection. But what sets them apart?

Q8 Van Gogh vs. Q8 Volta: What’s the difference?

Both product ranges meet the toughest OEM requirements and are suitable for gas, steam, and hydro turbines. However, there are subtle but important distinctions in performance level and application fit.

- Q8 Van Gogh is a high-performance turbine oil suited for a wide range of operating conditions. It offers excellent oxidation resistance, long service life, and protection against sludge and varnish formation.

- Q8 Volta, on the other hand, is an ultra-high performance oil designed for the most demanding environments. It delivers superior oxidative stability, better anti-varnish protection, and is ideal for combined cycle operations and geared turbines.

Think of Van Gogh as the versatile all-rounder, and Volta as the specialist for extreme conditions.

Both product lines are also available in EP (Extreme Pressure) versions — Q8 Van Gogh EP and Q8 Volta EP — where FZG value > 10 is required.

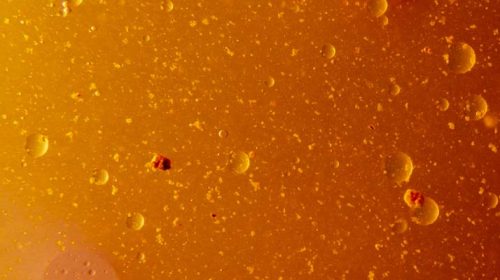

Why oxidation and varnish protection matter

One of the main causes of turbine oil failure is oxidation, which can lead to varnish build-up, decreased efficiency, and unplanned shutdowns. Q8 Van Gogh and Q8 Volta are formulated with exceptional oxidation and thermal stability, ensuring longer oil life even under continuous high-stress conditions.

This is backed by rigorous TOST testing (Turbine Oil Stability Test), which simulates extreme environments to evaluate oxidation resistance and service life. In side-by-side comparisons, both Q8 Van Gogh and Q8 Volta show strong results—with Q8 Volta slightly outperforming on key metrics like varnish control and oxidative endurance.

More than just a lubricant

Q8Oils lubricants prolong equipment life by reducing friction and wear, lowers the deposit formation and extends drain intervals. With more than 35 years of experience, Q8Oils combines world-class R&D, OEM-approved formulations, and expert technical support. The result? Lubricants that not only meet industry standards but consistently push them forward.

For electrohydraulic control systems, Q8Oils also offers Q8 Verne 46, a fire-resistant hydraulic fluid ideal for turbine governor controls, further extending the protection your systems need.

Why choosing the right lubricant is important for turbines

Choosing the right turbine oil means balancing reliability, performance, and efficiency. With Q8 Van Gogh, you get robust, versatile protection for standard to heavy-duty use. With Q8 Volta, you unlock maximum performance, even in the most extreme conditions.

Need help selecting the right product for your turbines? Contact our Q8Oils experts for tailored advice.