Q8 Brunel XF 700 range – the newest addition of lubricants to our popular Q8 Brunel series – is our most advanced range of soluble metalworking fluids for cutting and grinding.

Based on the latest technology of high purity synthesised base oils, combined with advanced chemistry and additive technology, these semi-synthetic fluids deliver outstanding performance balanced with safety and environmental protection.

The three fluids in the Q8 Brunel XF 700 range together cover all types of metal used in cutting and grinding operations. They can meet the challenges of even the most demanding materials, including aluminium alloys for the aerospace industry.

Their excellent performance has been proved by extensive laboratory testing and successful trials with manufacturers across Europe.

Benefits of Q8 Brunel XF 700 range

- free of polycyclic aromatic hydrocarbons (PAHs) and benzo[a]pyrene (BaP)

- high biostability (without using hazardous biocides)

- excellent ph buffer and corrosion protection

- superb emulsion stability

- superior wetting and detergency

- high protection against corrosion

- excellent machine cleanliness

The range includes:

XF711 - low content of lubricant base

Application: cutting/grinding of cast iron, carbon steel, low alloy steel. Suitable for welded tubes production (thanks to its high detergency).

XF 741 - medium content of lubricant base and ester

Application: cutting/grinding of ferrous metals and aluminium (no staining).

XF 753 - medium/high content of lubricant base

Application: cutting of steel alloys, stainless steel and aluminium alloys (no staining), including aerospace alloys.

Superior biostability

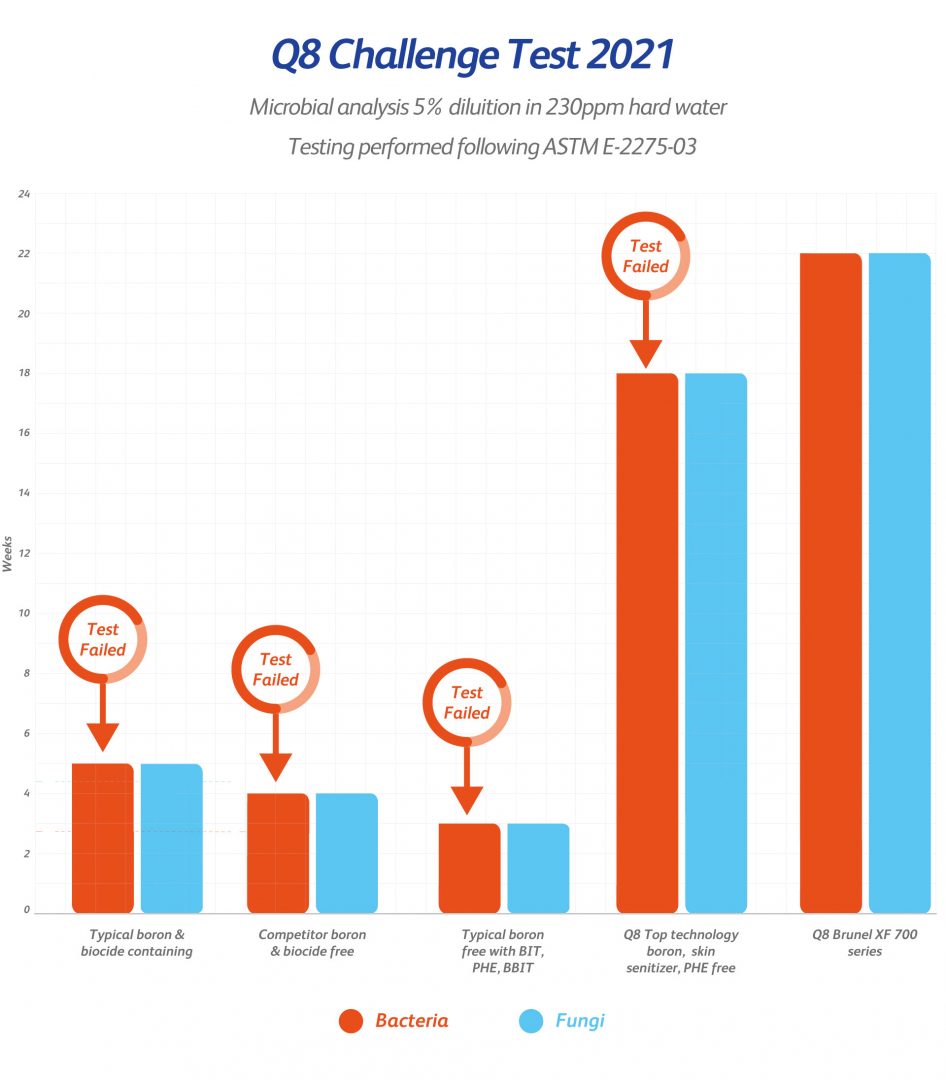

Tests prove the superior biostability of Q8 Brunel XF 700 compared with competitor lubricants.

We use the most exacting test to measure resistance to microbiological growth. Each week, we innoculate fresh emulsion with 106 cfu each of bacteria, fungi and yeast, and measure the level of contamination at the end of the week. The test ends when contamination remains at 106 cfu for two consecutive cycles.

For further details on the Q8 Brunel XF 700 range, please contact us on [email protected]