Our advanced cutting oil Q8 Brunel XF 700 is benefitting from a new technique that fights harmful contamination by fungi and bacteria. Developed internally and tested independently, it reduces the impact on the environment and operators compared with existing technologies.

Q8Oils chemists in Italy have formulated an innovative range of lubricants which are resistant to bacteria and fungi without using preservatives. This new formulation delivers a safer work environment, greater efficiency, and superior eco-sustainability.

Contamination of lubricants by fungi and bacteria can be a serious issue because of the problems it causes to the effectiveness of the lubricant. Feeding on substances such as nitrogen, phosphorus and carbon, fungi and bacteria can spread, resulting in lower pH, foam, unpleasant smell and eventually corrosion.

For these reasons, the proliferation of fungi and bacteria must be fought at all costs.

Lubricant producers have always used boron and biocides to prevent contamination, but these have many downsides. In aqueous solutions, boron derivatives tend to release boric acid which is harmful for humans; it is classified as toxic for reproduction and can affect fertility or damage an unborn child. Biocides are chemical substances that are used to destroy microorganisms, and these are also dangerous for humans. Producers no longer use formaldehyde donors because they release formaldehyde, which is carcinogenic if inhaled. Other groups of biocides (isothiazolinones – BIT, MIT, BBIT) are strong allergens, and others, such as phenoxyethanol (PHE) release phenol¸ a dangerous mutagen, in the emulsion.

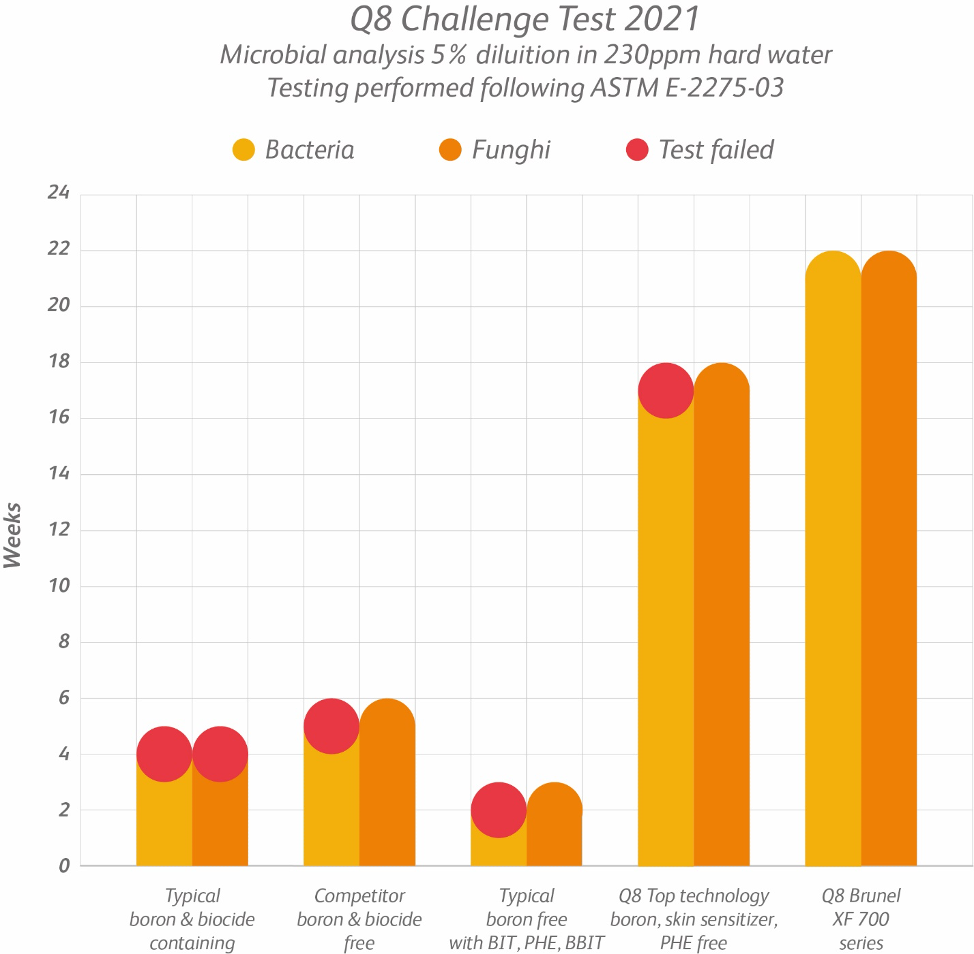

The exceptional biostability of Q8Oils’ new range of lubricants has been confirmed by the Challenge Test, which was conducted in an external laboratory. The test measures resistance to bacteria and fungi by injecting emulsions with aggressive strains of fungi and bacteria over several months. Each week, the lubricants are injected, and the proliferation of microorganisms is checked. If the bacteria and fungi have spread beyond a specific point (fixed at 10^6 cfu) over two consecutive weeks, the test is stopped and considered failed.

The results are easy to interpret; provided this point has not been reached, the lubricant is working effectively. Its strength is measured by the number of weeks it lasts.

Q8 Brunel XF 700 has achieved an outstanding result, outperforming all other products.