Aluminum wire drawing

Within wire drawing there are ever increasing demands to be more efficient, a faster, more reliable, zero defect production to meet the demands of the current economic climate.

In terms of costs and weight, it is seen in the industry that aluminum conductors are increasing the percentage of total production, in fact over the last ten years, aluminum overhead conductor production has increased by over 300%. However, in their manufacturing process and specifically how the aluminum or alloy wire is drawn, the manufacturing method has mostly stayed in the past and not taken advantage from increased performance and changes in drawing lubricant technology.

This paper then addresses the question of how can, a factory producing aluminum wire increase their production output?

In the present situation, the majority of aluminum rod and wire drawn is drawn using neat oils, a non-soluble wire drawing lubricant, it is fair to say that most likely over 90% of the world’s aluminum and aluminum alloys are drawn using neat oils, lets remind ourselves of neat drawing oils.

Neat Oils

Neat Oils for aluminum rod drawing can be in the viscosity range of Kinematic Viscosity (Kv40c) 100 to 500 centistokes by the method ASTM D445, the actual viscosity can be dependent on the lubricant supplier and formulation. Lower viscosity oils are typically used for intermediate and fine wire sizes where the drawing oil is of a Kinematic Viscosity (Kv40c) 30 to 100 centistokes.

Most neat oil formulations for aluminum wire drawing lubricants will use a single or combination of base oils with the properties of low sulphur and high oxidation resistance. The base oils are value added with performance additives of lubricity, EP and antioxidant additives. The choice of raw material additive is decided upon by the development chemist and there are thousands of performance additives to evaluate and consider for use.

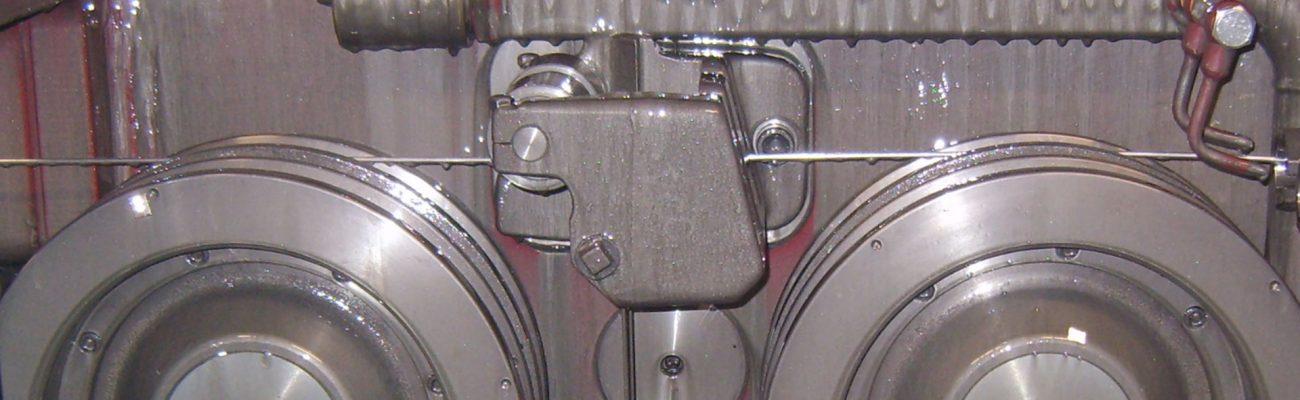

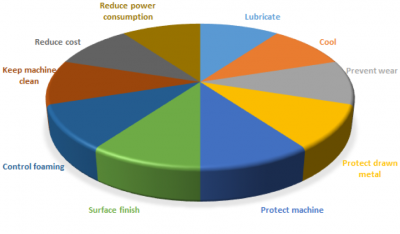

When a neat aluminum drawing oil is drawing rod and wire, it is developed to both lubricate and cool as per any other wire drawing product, lubricating at the wire/die surface and wire/capstan surface, removing and dissipating heat from the drawing process.

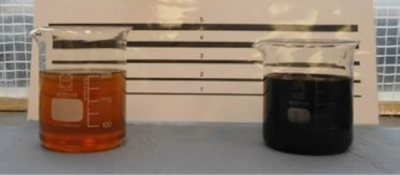

The aluminum drawing oil however, can over time become contaminated with aluminum oxides and fines from the drawing process. It can also become contaminated with moisture and free water from any leaks or contamination into the drawing oil. The fines can be abrasive to the die and capstan surface hence reducing their life, this can also affect the wire surface finish of the drawn wire due to poor dies and is costly. Additionally, the fines present in the drawing oil can react with the lubricant to cause the formation of aluminum soaps and darken the colour of the drawing oil, with severe contamination the drawing oil can exhibit thixotropic properties.

The operating temperature and temperature control of aluminum neat wire drawing lubricant also has a direct influence on drawing performance where excessive aluminum soaps can be formed which can influence viscosity and thereby change how the drawing oil will lubricate and cool.

Lubricant viscosity increase or thickening can be caused by three principle causes:

- Reaction of aluminum fines in the system with the lubricant to form aluminum soaps, this reaction is catalysed by temperature, therefore the higher the drawing oil temperature, the rate of reaction is increased.

- Contamination with finely dispersed aluminum particles, large particles can settle or be removed easily by filtration and therefore have little effect on the lubricant viscosity. Small finely dispersed particle remain in colloidal suspension, almost thixotropic effect which can increase viscosity and reduce lubrication.

- Lubricant oxidation, which would be a reaction of the lubricant or particular components of the lubricant with the atmospheric oxygen. Temperature can also accelerate this reaction, particularly when bulk oil temperatures exceed 50 degrees centigrade.

Effects of water contamination

The effects of water contamination into drawing oil can be both severe and costly. Free moisture can cause severe lubrication problems in the drawing die to give a scored or severely marked drawn wire.

The figure above shows wire scoring from the contamination of a drawing oil with water droplets into the die.