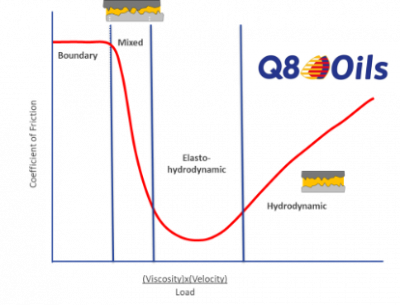

Lubrication is divided into several regimes:

Hydrodynamic lubrication (HL)

Hydrodynamic lubrication (HL) is defined as a system of full fluid film lubrication that has sufficient pressure to separate two sliding surfaces. The lubricant film is so thick that the opposing surfaces are prevented from coming into contact. The lubrication is governed by the bulk physical properties of the lubricant, notably the viscosity. Viscosity is an important factor in determining the capabilities of a hydrodynamic lubricant film. Sometimes the hydrodynamic lubrication regime is referred to as ‘viscosity-pressure’ lubrication. The friction coefficient is mainly dependent on the fluid viscosity.

Elastohydrodynamic lubrication (EHL)

Elastohydrodynamic lubrication (EHL) is a form of hydrodynamic lubrication, where elastic deformation of the surfaces becomes significant. There are two types of EHL, hard and soft. Hard EHL relates to materials of high elastic modulus, like metals. In this lubrication regime, the viscosity-pressure effect and elastic deformation are equally important. Soft EHL relates to materials like rubber.

Mixed lubrication (ML)

Mixed lubrication (ML): when the pressure in EHL is too high or the speeds are too low, the lubricant film will break. Some contact between the asperities of the surfaces and partial full film lubrication will occur. This lubrication regime is called mixed lubrication (ML) and is a combination of hydrodynamic and boundary lubrication.

Boundary lubrication (BL)

Boundary lubrication (BL) is described as a type of lubrication where the lubricant does not separate the two surfaces with a fluid film and there is considerable contact between the asperities. The lubrication mechanism is governed by the physical and chemical properties of the lubricant. The physical properties of the bulk lubricant become less important and the friction coefficient is less dependent of the fluid viscosity. In boundary lubrication, the friction is defined by the properties of the surfaces and the lubricant film, other than the viscosity, at the interfaces. Boundary lubricants can be defined as extremely thin films that are present on the metal surfaces. A type of boundary lubrication is extreme pressure (EP) Lubrication. EP lubricants contain EP additives. These EP additives react under increased energy systems and with the metal surface, resulting in a chemical film. This chemical film prevents metal-to-metal contact.

Some forming applications can use different lubrication regimes.

Metalforming processes - starting from strip

There are many forming operations and here we describe the two most common forming operations:

blanking (and similar operations) and drawing operations.

Q8Oils has specialist expertise in wire drawing and cold rolling oils for stainless and copper strip. We have published some articles referring to these typical forming operations, please check Q8Oils.com.

Blanking operations

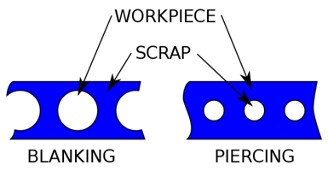

Blanking, punching and piercing are shearing processes in which a punch and die are used to modify webs. In blanking, the punched out piece is used and called a blank; in piercing/punching the punched out piece is scrap.

The simple description of the drawing process is that the punch is forcing a metal strip (blank) from a blank holder into and through a forming die, reshaping the flat strip into a three-dimensional shape, like a cup or pan. There are degrees of severity of these drawing operations and therefore several definitions to define the severity of the forming. On the factory floor, the rule of thumb for a deep drawing operation is whether the cup depth is equal to or greater than the cup width.

An easy way of defining the severity of a drawing operation is by the draw ratio (DR):

| Draw ratio (DR) = |

|

| Severity classification of drawing | Draw Ratio |

|---|---|

| Low | <1.5 |

| Moderate | 1.5 – 2.0 |

| Deep | >2.0 |

In low to moderately severe drawing operations there is almost no or little wall thinning. In deep drawing operations wall thinning may occur. The severity of drawing operation is not only affected by the depth of drawing, but also by the amount of wall thinning that occurs within the side walls.

Beside the severity of drawing, the drawability of the metal used is often expressed as the ratio of the blank diameter to the punch diameter. This ratio is the limited draw ratio (LDR):

| Limited Draw Ratio (LDR) = |

|

LDR is often used to communicate the maximum reduction possible. There are many factors influencing a successful drawing operation such as the type of metal, thickness, metal quality and blank holder pressures. These should be optimised to achieve the desired quality and productivity.