Car manufacturers and OEMs have developed a range of different technologies to electrify the powertrain of vehicles. In this article we give an overview of the different engine technologies, the market figures and the lubrication specificities of hybrid and electric vehicles.

To reduce CO2-emissions, OEMs have been looking at low emission engine technologies as an alternative for internal combustion engines (ICE). Currently, there are different electrified solutions on the market, from mild hybrid electric to full electric vehicles.

Overview of engine technologies

The passenger car market holds a diverse range of engine technologies:

- Internal Combustion Engine (ICE)

- Internal Combustion Engine (ICE) with Start/Stop Technology

- Mild Hybrid Electric Vehicle (M-HEV): The electric motor cannot propel the vehicle on its own. It is used for starting the engine, acceleration assist and regenerative braking. This technology is used in the Honda Civic.

- Full Hybrid Electric Vehicle (F-HEV): The electric motor can power the car unassisted while the is battery charged by the combustion engine. This technology is used in the Toyota Prius.

- Plug-in Hybrid Electric Vehicle (P-HEV): This engine is similar to F-HEV where the battery can be charged externally or via the combustion engine. This technology is used in the Ford C-max Energy.

- Electric Vehicle (BEV): Battery driven electric motors and controllers used for propulsion. This technology is used in all Tesla models.

- Range Extender Electric Vehicle (REEV): A BEV which also carries an ICE driven electric generator to supplement the batteries. This technology is used in the BMW I3.

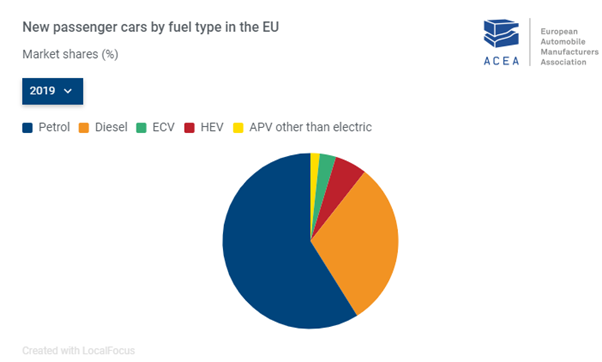

Market acceptance of hybrid- and electric vehicles

Full hybrid electric vehicles (FHEV) with additional features such as regenerative braking or stopping the engine during idle, can significantly improve fuel economy and lower CO2 emissions. It makes them increasingly popular with OEMs as a way to reach European emission legislation.

A number of large manufacturers are developing FHEVs because they see the technology as a good bridge until more advanced diesel and electric vehicles are fully developed.

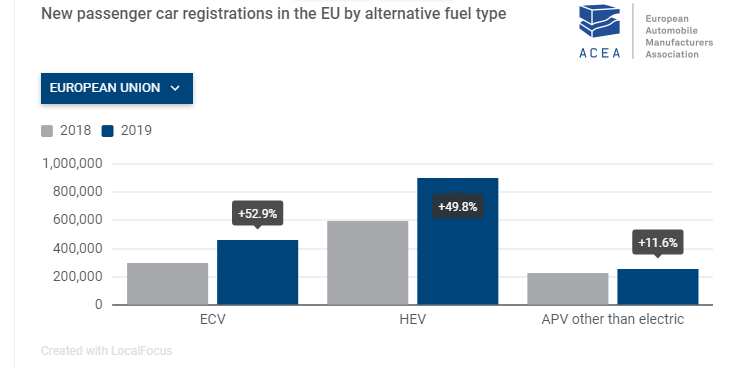

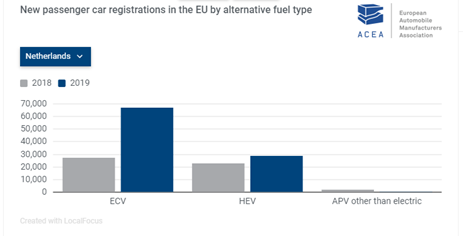

Gaining the global acceptance of hybrid- and electric vehicles by consumers remains a big challenge. In Europe 10% of last year’s car sales consisted of hybrid- and electric vehicles. In the Netherlands they accounted for close to 100.000 new vehicles in 2019, which is close to 25% of the new car sales registrations.

Lubrication of hybrid cars

Hybrid vehicles introduce new powering architectures with average engine loads that are significantly higher and engine operating times that are much shorter. These special circumstances require special lubrication solutions:

- Engine oil

- Oil for the drivetrain

- Manual Transmission fluids (MTF)

- Automatic Transmission Fluids (ATF)

- Dual Clutch Transmission Fluids (DCT)

- Continuously-variable transmission (CVT)

- Engine coolants

Lubrication challenges of hybrid vehicles

During speeding up, a hybrid vehicle switches from one to the other engine at the proper time, yielding a win-win in terms of energy efficiency. This is translated into lower fuel consumption and reduced CO2-emission.

However, it also brings some specific challenges:

- When the combustion engine kicks in when the hybrid car is already travelling at speed, it introduces a heavy load on cold start, increasing the risk of engine wear.

- Because the operation time of the combustion engine is short it is more prone to moisture and acid formation.

- Under-usage of the combustion engine can lead to fretting wear.

- Short journeys during which only the electric motor is used, increase the risk of water accumulation in the combustion engine.

These special engine operating conditions result in low oil temperatures for which the additive chemistry has to be compatible. In this harsh environment, water ingress and sludge formation can cause serious oil degradation over time. In combination with the use of bio-fuel, this can further accelerate the oil degradation process in HEV-applications. It means only the highest quality engine oils are suitable for hybrid vehicles.

Hybrid lubricants from Q8Oils

Q8oils develops new dedicated engine oils for hybrid vehicles and new dedicated transmission oils for the driveline for both hybrid- and electric vehicles.

They deliver an instant start-up lubrication in cold conditions, minimizing friction and start-up wear. They reduce fuel consumption and CO2-emissions, protecting the environment.