Micro-organisms can be defined as living organisms which can only be seen by the use of a microscope. The Microbial world is extremely diverse and consists of single and multi-celled organisms. Of most interest in metalworking fluids are bacteria and fungi.

Bacteria

Bacteria are a large group of single celled organisms typically a few micrometres in length. There are thousands of known species of bacteria on earth, and they can occupy every habitat on the planet making up much of the planet’s biomass.

Bacteria commonly found in metalworking fluids

Aerobic

- Pseudomonas oleovorans

- Pseudomonas aeruginosa

- Achromobacter sp

Anaerobic

- Escherichia coli

- Staphylococcus sp

- Bacillus cereus

- Clostridium sp

- Desulfovibrio sp (SRB)

As with all living species bacteria depend on an energy source (light, chemical) and a carbon source (organic compounds, CO2) for metabolism. Bacteria also require nutrients and favourable conditions such as pH and temperature to proliferate. These conditions depend on the type of bacteria;

- Aerobic bacteria – require Oxygen

- Anaerobic bacteria – do not require Oxygen

Anaerobic bacteria include sulphate reducing bacteria (SRB’S) which can be attributed to the strong objectionable odour of ‘rotten eggs’. They can also cause severe, dark staining on machines and work pieces.

Bacterial growth & Proliferation

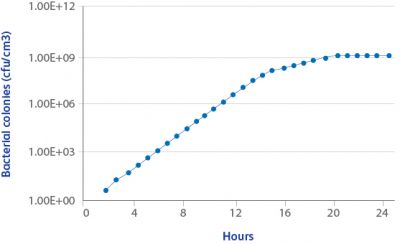

Under optimal conditions, bacteria can divide every 10 to 20 minutes creating logarithmic growth until a maximum sustainable density of population (bio-mass) occurs.

Bio film formation

A bio film is formed when bacteria attach to a surface and are left undisturbed. A polymer is secreted which traps other microbes and particulates, forming a film. This film contains a mix of microorganisms including aerobic and anaerobic bacteria in a highly stable environment which is very difficult to penetrate.

Fungi, Yeast & Moulds

Fungi and moulds are multi celled and large in comparison to bacteria (>2цm).

Fungal contamination can be a problem as it produces both biomass and toxins. The build-up of biomass can be a particular problem because it grows as a “mat which needs to be physically removed.” Fungi can feed on minerals in water so where possible the ideal ‘make up’ water for metalworking fluid is deionised.

Common types of Yeast & Fungi found in metalworking fluids are:

- Aspergillus sp

- Acremonium sp

- Candida albicans

- Penicillium sp

- Geotrichum candidum

- Trichoderma sp

Yeasts are single celled fungi which can be both aerobic and anaerobic. Yeasts prefer neutral or a slightly acidic pH environment.

Bio deterioration of metal working fluids

A typical metal working fluid can consist of various organic components such as fatty acids, esters, surfactants, sulphur and phosphate compounds plus contamination such as tramp oil. All of these can provide ideal nutrition for bacteria resulting in a significant impact on fluid performance.

Emulsion characteristics

Microbial activity can change emulsion characteristics either by increasing foaming or by splitting the emulsion due to the production of organic acids and bio-surfactants.

Fluid performance

Micro-organisms can metabolise lubricity additives which are then degraded and broken down and their functionality lost or reduced as a result.

Corrosion Inhibition

Microbes can affect MWF corrosion properties through the generation of organic acids and enzymes which attack metal surfaces.

Aesthetics – Odour & Slime

The common phenomenon of ‘Monday morning odour’ is as a result of microbial metabolism. This results in the generation of organic acids and aldehydes with characteristic odours to the more potent gases such as hydrogen sulphide. These gases are allowed accumulate during a shutdown and are released as the fluid is re-circulated.

Health Effects

The risk to health of microorganisms in metal working fluids includes infection, reaction to toxins and allergic reactions. The risk can be significantly increased where there are improperly treated wounds such as cuts and abrasions. Good personal hygiene and the correct PPE are always recommended.

Condition monitoring

Observations

Malodours and slime residue are a clear indication of microbiological activity. Tramp oil pooling can promote the proliferation of bacteria and every attempt should be made to remove it. Visual inspection and detection of poor hygiene and house keeping such as pools of liquid, accumulation of rubbish and poor personal hygiene will exacerbate any incidence of microbial contamination.

Microbiological tests

The most common way to test for the presence of microbiological contamination is to take a sample from the fluid or surface and cultivate on a supporting media (Agar).

A simple and convenient method is the use of pre-made ‘dip-slides’. These contain agar on each side and depending on the type of dip-slide, support the growth of bacteria on one side (identified by red spots) and fungi and yeasts on the other.

Note that the assessment of anaerobic bacteria is limited due to the presence of oxygen; this does not mean however that they are not present.

Interpreting the level of microbiological contamination

Below is a guideline as to what level of contamination is considered significant and what cause of action is advised;

| Level of contamination CFU = colony forming units per gram or cm³ |

|

|---|---|

| <10³ | slight contamination Contamination is being maintained at low levels; fluid should be monitored in case further proliferation occurs |

| <104 – 105 | moderate contamination Ensure all good practice checks and actions are being applied (concentration, pH, tramp oil, agitation and flow). A biocide addition maybe recommended to limit any further microbial proliferation. |

| <10⁶ and above | Very high contamination Immediate action should be taken. An addition of a biocide may reduce / limit further contamination however, in the long term, draining and cleaning is advised. |

To control or reduce the rate of bacterial growth:

- Select a product with bio stable credentials – Q8 Baroni, Q8 Berlioz and Q8 Brunel

- Sterilise your machine system prior to installing a new fluid

- Ensure correct mixing procedures are followed

- Keep the machines as clean a possible regularly removing chips and swarf

- Remove oil contamination – “Tramp Oil”

- Maintain fluid concentrations within recommended parameters