Manufacturing cold rolled strip of copper, copper-alloys and stainless steel-alloys require cold rolling oils that are integral to the manufacturing process of high-quality strip. Cold rolling oils are important to balance friction, improve surface finish, extend the life of the work rolls, cool the strip and rolls, flush particles, and much more.

Market shows trends towards thinner sheets, better surface finish, higher productivity, and saving costs.

Q8Oils is committed to formulate the cold rolling oils that can support these continuous improvements.

Viscosity

Reducing viscosity of a cold rolling oils is one of the important topics that can improve the gloss, improve the oil removal from the strip, increase rolling speeds, give a better cooling, and more. In previous articles we have described the importance and impact of viscosity on the cold rolling process.

Many strip manufacturers have a concern to decrease or use lower viscosity cold rolling oils. One of the most important concerns is the flash point and this article elaborates on the relationship between viscosity and flash point.

Flash point

The flash point of an oil is the lowest temperature at which it can vaporize to form an ignitable mixture in air. At the flash point temperature, the vapor can ignite when exposed to an ignition source (e.g. spark).

Relationship Viscosity and Flash point

With the typical cold rolling oil viscosities in the range of 4 – 10 mm2/s, the additives have very limited or no influence on the flash point. The flash point is a key property of the base oil used to formulate a cold rolling oil, and therefore the relationship between base oil viscosity and flash point will be further explained.

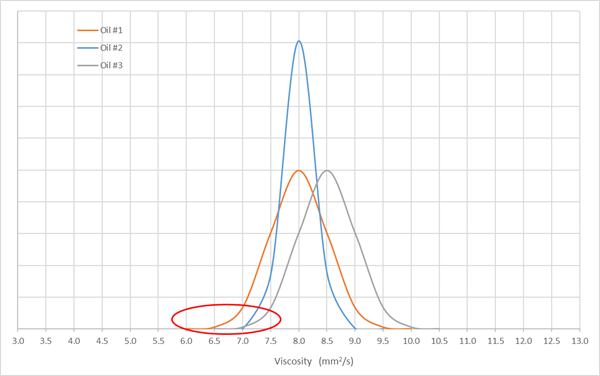

Base oil exists of a variety of hydrocarbon molecules and is as such not a pure substance. However the molecules are very similar and their differences are their molecular sizes, typically a range following a normal, gaussian distribution as displayed in the graph below.

Oil #1 and Oil #2 have the same viscosity of 8.0 mm2/s, but a different range of molecular sizes. Oil #1 has a broad range whereas Oil #2 has a much narrower range. This difference in distribution has a significant impact on the amount of small molecules (marked red) and large molecules present in the oil.

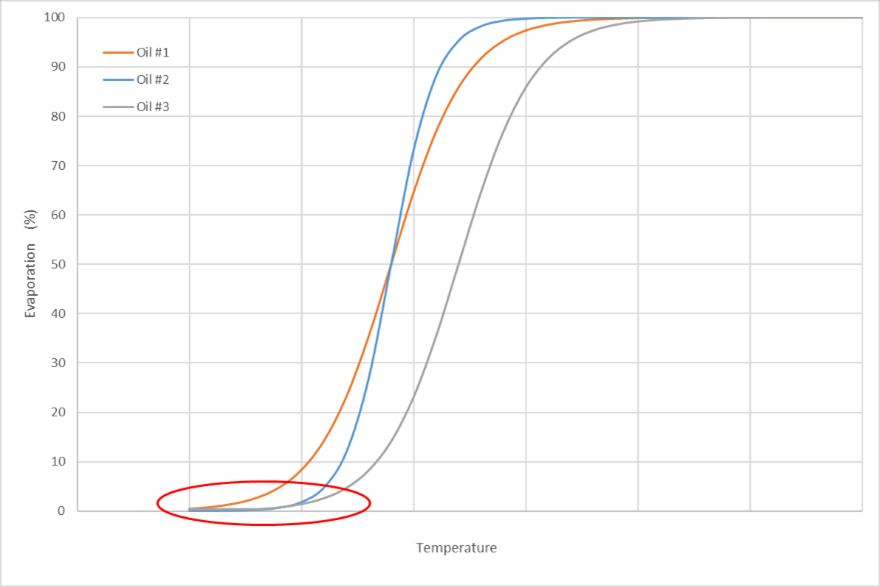

The small molecules are responsible for the flash point. Small molecules are the first to start to evaporate upon increasing the temperature. In the next graph the evaporation curves are displayed. Clearly the Oil #1 has more small molecules that evaporate at lower temperature than the other oils and consequently, the flash point of Oil #1 is lower than the other two oils.

Interesting to understand how the flash point can be increased. The first, classic approach is to keep the same type of base oil, but increase the viscosity. For example Oil #3 has similar distribution characteristics, but overall with larger molecules. Therefore, in this example a base oil with viscosity of 8.5 mm2/s is displayed and clearly less small molecules are present. Consequently the flash point increases significantly. However, the average molecular size is larger and also larger molecules are present than in Oil #1. This may have negative influence on the oil removal and annealing behavior. After rolling more oil could be left on the strip, and this oil may also be more difficult to remove. And a higher viscosity cold rolling oil has other negative aspects as mentioned in the first paragraphs.

A second approach to increase the flash point could be to switch to another base oil type with narrower distribution, e.g. Oil #2. As this oil has also less amount of small molecules, the flash point increases compared to Oil #1 and is quite similar to the flashpoint of Oil #3. In this case the average molecular size is not increased, so the viscosity remains at 8.0 mm2/s. From a rolling operation point of view, Oil #2 should perform equal or better than Oil #1. A big advantage is the reduction of larger molecules, improving the oil removal and better evaporation in the annealing oven.

Remarks

Q8Oils work closely together with customers to improve their cold rolling process with customized oil compositions. An important part of improvements is the correct understanding of all requirements, the operation parameters of the cold rolling mills and other steps in the entire process.

For more information, please contact our Rolling Team at Q8Oils.