In modern machining environments, precision and productivity are non-negotiable. Yet behind every high-quality finished part lies a series of supporting processes that are often taken for granted. One of them is industrial cleaning.

Cleaning is essential to remove machining residues, protect components, and ensure consistent downstream performance. However, traditional cleaning processes are frequently associated with high water consumption, increased waste streams, additional disposal costs, and unnecessary downtime.

Designed for Modern Machining Environments

Q8 Corelli CRX is engineered to meet the demands of today’s precision metalworking operations. It is effective against typical machining residues such as soluble oils, light-duty neat cutting and forming oils, thin corrosion preventive films, lubrication oils, and general swarf and dirt.

Optimised for use in modern spray, intensive flood-wash, and high-pressure cleaning equipment, Corelli CRX ensures thorough removal of contaminants while protecting both components and equipment.

Key performance characteristics include:

- Low-foam behaviour, reducing the risk of pump damage and unplanned downtime

- Superior demulsifying properties, allowing easy oil separation and extended bath life

- Temporary corrosion protection, helping to lower scrap rates after cleaning

- Versatile compatibility with multiple metals and varying water qualities

These features contribute to a cleaning process that is reliable, low-maintenance, and aligned with high-throughput production environments.

The Hidden Cost of Traditional Cleaning

In many workshops, cleaning fluids are treated as single-use consumables. After removing oils, corrosion preventives, and swarf from machined parts, the used solution is discarded and replaced. While this approach may appear straightforward, it introduces several hidden inefficiencies:

- Increased water consumption

- Higher disposal and replenishment costs

- Fluid carry-over losses

- Additional maintenance and downtime

Over time, these factors directly affect operational costs and environmental performance. Cleaning, once considered a necessary side step, becomes a limiting factor in overall process efficiency.

Efficiency That Extends Beyond Cleaning

The benefits of optimised cleaning extend well beyond the cleaning stage itself. By reducing carry-over losses and stabilising coolant performance, manufacturers can achieve longer fluid lifetimes and more consistent machining conditions.

Effective cleaning at low temperatures also contributes to improved energy efficiency, helping to reduce the overall CO₂ footprint of the operation. This makes Corelli CRX not only a technical solution, but also a practical step towards more sustainable manufacturing.

Rethinking Cleaning as Part of the Process

At Q8Oils, we believe that every stage of the machining process offers opportunities for optimisation. Cleaning should not be viewed as a standalone activity, but as an integrated part of the entire metalworking system.

This mindset has led to the development of Q8 Corelli CRX, a high-performance industrial cleaning fluid designed to go beyond conventional cleaning. Instead of generating waste, Corelli CRX supports a closed-loop approach that turns cleaning into a value-adding step within the machining process.

Closed-Loop Efficiency in Practice

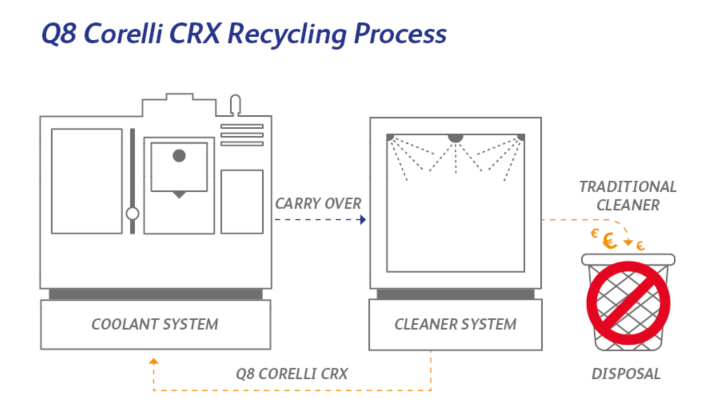

What sets Q8 Corelli CRX apart is its compatibility with the Q8 Brunel XF 700 coolant range. Together, they enable a unique closed-loop cleaning and machining concept.

Rather than discarding the used cleaning solution, Corelli CRX can be seamlessly reintegrated into the coolant bath. This approach delivers measurable operational benefits:

- Reduced waste through recycling of the cleaning fluid

- Lower disposal costs and reduced fresh fluid consumption

- Less water usage, supporting resource conservation

- Improved productivity thanks to fewer interruptions and fluid changes

The result is a more stable process where cleaning and machining work in harmony instead of competing for resources.

From Necessary Cost to Strategic Advantage

By integrating cleaning into a closed-loop system, manufacturers can transform a traditionally cost-driven process into a strategic advantage. Reduced waste, lower water consumption, improved productivity, and enhanced equipment protection all contribute to a more resilient and future-proof machining operation.

Optimised cleaning is no longer just about removing residues. It is about improving efficiency across the entire process chain — from machining performance to sustainability outcomes.

Ready to Optimise Your Cleaning Process?

Every machining environment is different, and the true value of closed-loop cleaning lies in correct implementation. Q8Oils’ technical specialists are ready to support you in evaluating your current cleaning and coolant setup and identifying opportunities for optimisation.

Discover how Q8 Corelli CRX, in combination with Q8 Brunel XF 700, can help close the loop in your machining process — improving efficiency today while supporting a more sustainable future.

Read more: Corelli CRX product data sheet

Learn more: Corelli CRX brochure

Or contact us today for any questions.